-

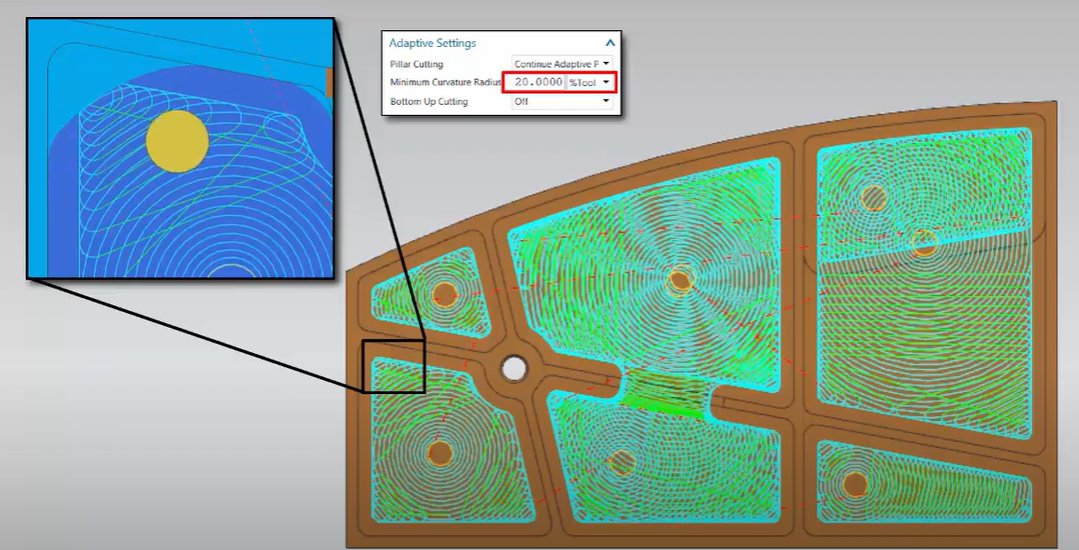

Adaptive Milling – Minimum Curvature Radius and Cut Depth

- September 21, 2020

- Posted by: Sapience

- Category: Blog

No Comments

The New minimum curvature radius option in Adaptive milling gives you better cutting control in corners by preventing small cuts which can cause excessive tool wear particularly machining hard materials. Previously, the minimum curvature radius was set to zero which left no stock in corners and produce many small cuts with small arc lengths. The

-

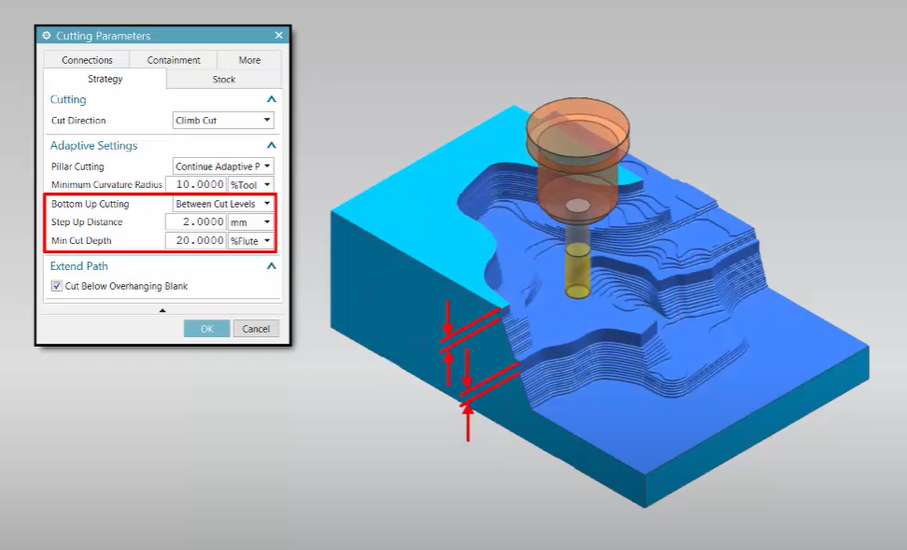

Adaptive Milling – Bottom Up Cutting Methodology

- September 21, 2020

- Posted by: Sapience

- Category: Blog

Bottom Up Cutting in Adaptive Milling can be used to control stock removal between cut levels. Typically, Adaptive milling establishes cut level that utilizes as much as the tool flute length as possible. Without Bottom up cutting, it leads to excess amount of stock remaining between the levels. With bottom up cutting, the tool path

-

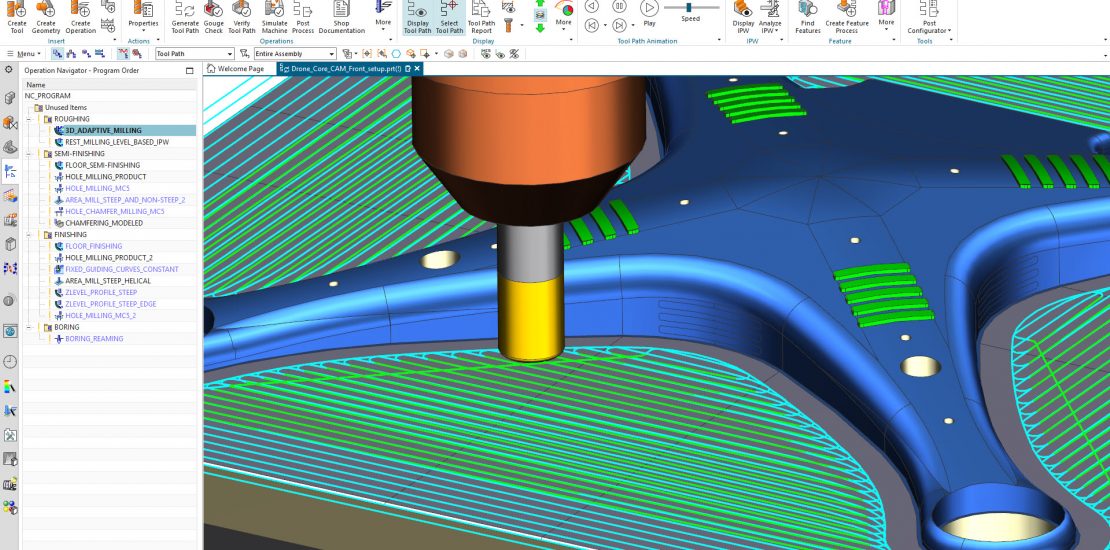

Adaptive Milling – New Technological Enhancement for High Speed Machining

- September 17, 2020

- Posted by: Sapience

- Category: Blog

Adaptive Milling, a new technological enhancement provided in NX, is an ideal solution for high speed machining. It is a highly efficient roughing strategy for hard materials at high speeds. In this blog post, we are going to present an overview of Adaptive milling in NX 12. What is Adaptive Milling? It is an innovative

-

Design for Manufacturing using Siemens NX Solutions

- September 8, 2020

- Posted by: Sapience

- Category: Blog

Design for manufacturing (DFM) is a methodology where products are designed with an intent of accelerating time to market while reducing the product cost, without compromising the quality. Siemens NX platform offers integrated solutions that can enable users to seamlessly work from product design to manufacturing. NX CAD, a highly versatile design solution, supports users at